Centrifugal pumps transport liquids by using pressure. Because they are relatively uncompressible, the liquids are not condensed or pressurized; instead they are imparted with centrifugal force, the force that causes substances to move away from their center of rotation. Read More…

At Armstrong Fluid Technology, we pride ourselves on our expertise in designing and manufacturing innovative fluid management solutions, with a strong emphasis on centrifugal pumps. Our commitment to engineering excellence enables us to provide high-performance products that meet the diverse needs of our clients across various industries.

Fistam Pumps is driven by innovation. Manufacturing four lines of high quality centrifugal pumps, we consider the interaction of a pump and its system to develop the optimum solution for every client. Stainless steel ensures hygienic use for chemical and water pumps in any application. We invest in research and development so you can expect superior quality and performance in every Fristam pump.

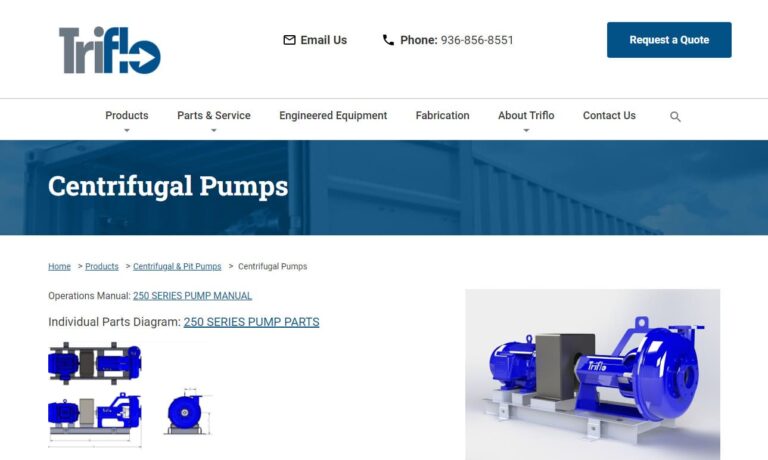

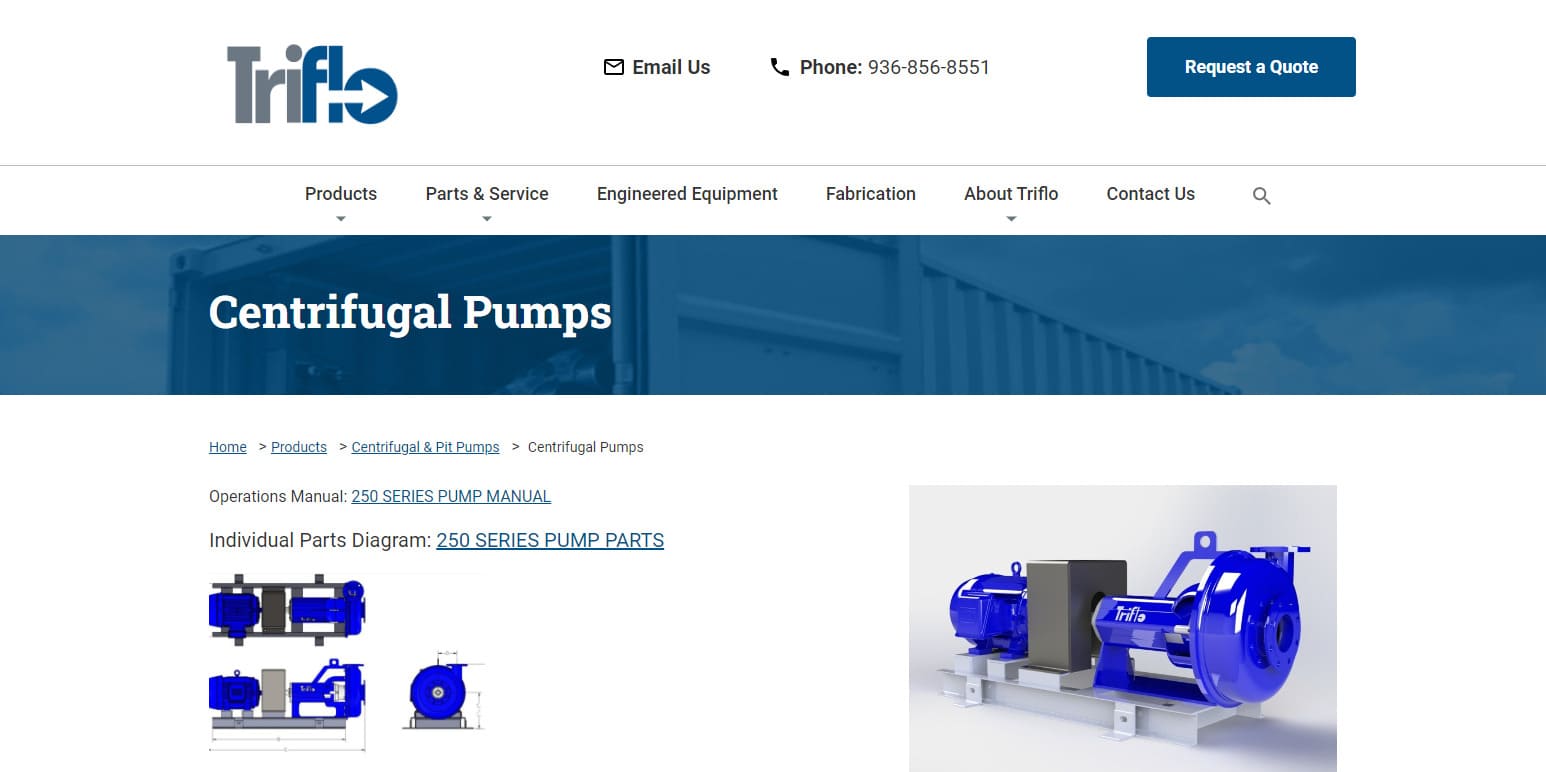

Triflo International, Inc. designs and manufactures solid separation equipment. The company’s products include shakers, desanders, desilters, mud cleaners, mud gas separators, vacuum degassers, and mud systems; and fast move mud systems, skidded mud systems/tanks, HDD and trenchless mud systems, dredging and dewatering systems, and solids control equipment, as well as soil washing, dewatering,...

Tramco Pump is proud of our inventory and quick delivery of parts, pumps and custom designed systems. Our impressive line includes centrifugal pumps offering flows to 75,000 GPM heads to 2,200ft as well as vertical, sewage and sump, rotary, diaphragm pumps and more to ensure your needs are met. With testing, repair and preventative measures; Tramco delivers the best products with the best service.

More 12 Volt Pump Manufacturers

12 volt pumps are constructed out of aluminum, cast iron or stainless steel though some models have plastic housings. Because of the low amount of power these pumps use (less than one horsepower), the output is much lower than that of general purpose, industrial or commercial grade pumps. They are frequently small and compact enough to be portable and consequently are used for temporary jobs. 12 volt pumps are found on personal watercraft for water bailing purposes in case of emergency.

They are also used for camp or outdoor showers, watering gardens and pumping out a flooded basement. There are three main kinds of centrifugal pump usages: chemical, water and trash. Because of their size and energy, 12 volt pumps are generally not designed to pump the solids and debris usually found in waste water. Depending on the construction, however, some 12 volt pumps may be used to transfer small batches of liquid chemicals.

Centrifugal pumps are basic machines with few parts. The central component is an impeller which is very similar to a propeller except that the blades are not as sharp and they create suction instead of propulsion. The impeller is kept in a volute, or casing, and is mounted on a rotating shaft that connects to the motor.

As mechanical energy powers the shaft, the impeller turns as well, its vanes imparting kinetic energy to the fluid which follows the expanding volute to the discharge opening. Though the speed of the liquid is reduced, the pressure increases; 12 volt pumps can transport up to 10 gallons per minute. The maximum lift is about 30 feet with small or miniature pumps offering around 5 feet of lift. The pump diameter for a 12 volt centrifugal pump is often just a few inches.

Miniature 12 volt pumps are handheld and can be dropped into a well hole or river to lift water. Some models are submersible while others are able to run dry. Accessories are available to suit the demand and include removable strainers, hose barb connections and anti-clog measures. Many of these pumps need to be primed before they are used to expel air and allow water to be drawn in by the suction.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services