A well pump is an electromechanical device installed after a well is drilled or dug. A well pump transports water from the well to another place. The well’s water is pumped through a pipe or jet by a centrifugal pump powered by an electric motor. The well pump raises water and delivers it to the authorized water system or home. The most widely used pumps today are jet pumps and submersible pumps. Both of these pumps use centrifugal force to lift water. Impellers (spinning rotors) produce a vacuum that propels water through the well casing into the distribution system. Read More…

At Armstrong Fluid Technology, we pride ourselves on our expertise in designing and manufacturing innovative fluid management solutions, with a strong emphasis on centrifugal pumps. Our commitment to engineering excellence enables us to provide high-performance products that meet the diverse needs of our clients across various industries.

Fistam Pumps is driven by innovation. Manufacturing four lines of high quality centrifugal pumps, we consider the interaction of a pump and its system to develop the optimum solution for every client. Stainless steel ensures hygienic use for chemical and water pumps in any application. We invest in research and development so you can expect superior quality and performance in every Fristam pump.

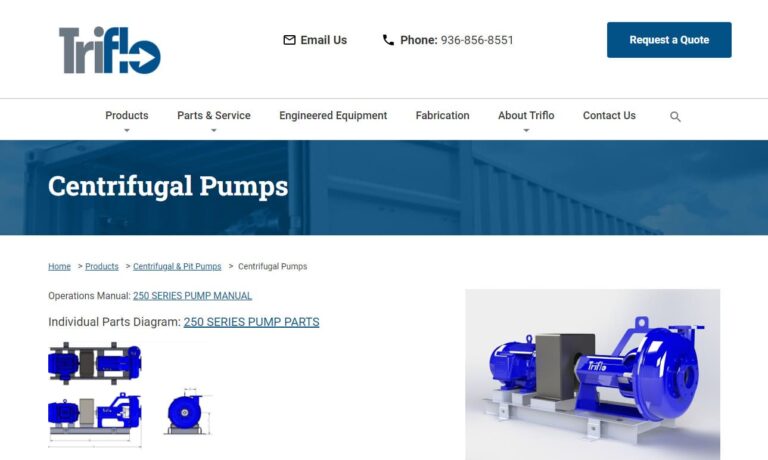

Triflo International, Inc. designs and manufactures solid separation equipment. The company’s products include shakers, desanders, desilters, mud cleaners, mud gas separators, vacuum degassers, and mud systems; and fast move mud systems, skidded mud systems/tanks, HDD and trenchless mud systems, dredging and dewatering systems, and solids control equipment, as well as soil washing, dewatering,...

Tramco Pump is proud of our inventory and quick delivery of parts, pumps and custom designed systems. Our impressive line includes centrifugal pumps offering flows to 75,000 GPM heads to 2,200ft as well as vertical, sewage and sump, rotary, diaphragm pumps and more to ensure your needs are met. With testing, repair and preventative measures; Tramco delivers the best products with the best service.

More Well Pump Manufacturers

When choosing a well pump, one should consider the depth of the well and how much each water each dwelling needs. Well pumps can handle water, oil, gas, less hazardous chemicals, slurries, and wastewater. Well pumps are often used for household wells, agricultural water distribution, mining, or other fuel production applications.

Types of Well Pumps

Pumps for water wells come in two varieties, deep well pumps and shallow well pumps. Shallow well pumps sit above ground and use suction pipes to draw water. A shallow well suction pump's typical maximum sea-level depth is 25 feet. Shallow good pumps are used when the water is close to the surface or in an artesian well. Deep wells often use jet pumps.

Jet pumps

There are jet pumps for deep and shallow wells. Shallow well jet pumps work well with a depth of 25 feet. Deep well pumps are more powerful and able to operate in depths of 100 feet. However, because the pump's motor will have to work harder, the efficiency will decrease as the well depth increases. Sand damage to jet well pumps is common.

Deep well pumps can sit on the surface or be submersible. Most well water pumps deliver well water to residences in rural areas. These electric pumps are typically submersible, enclosed, and powered by standard household AC power. In addition, they have a die-cast top that enables them to be serviced by underground electrical cables.

Submersible Well Pump

The submersible pump is the most common pump, popular for its adaptability. Submersible well pumps can be used no matter the well’s depth. As their name suggests, submersible pumps are situated deep inside the well, underwater. These pumps are low-maintenance, long-lasting, and watertight. The pump must be removed from the well and brought to the surface to be repaired.

Submersible pumps have a motor that powers impellers to propel water up the pipe. Then, the water enters a surface tank for use. Submersible pumps can be expensive and susceptible to corrosion. However, they are less prone to mechanical failure than aboveground pumps.

Choosing the Right Well Pumps Supplier

To make sure you have the most positive outcome when purchasing Well Pumps from a Well Pumps Supplier, it is important to compare at least 4 or 5 Companies using our list of Well Pumps suppliers. Each Well Pumps Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Well Pumps company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Well Pumps businesses with the same quote.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services